At Nashira Hardmetals, we know that working in a sustainable way means choosing innovative, cutting-edge solutions that reduce our impact on the environment.

At Nashira Hardmetals, we know that working in a sustainable way means choosing innovative, cutting-edge solutions that reduce our impact on the environment.

For a company, generating value means strategically managing all the available resources. This is why we have been working towards environmental sustainability for more than 10 years by installing a photovoltaic system, using recycled packaging and carefully organising our internal operations to reduce waste.

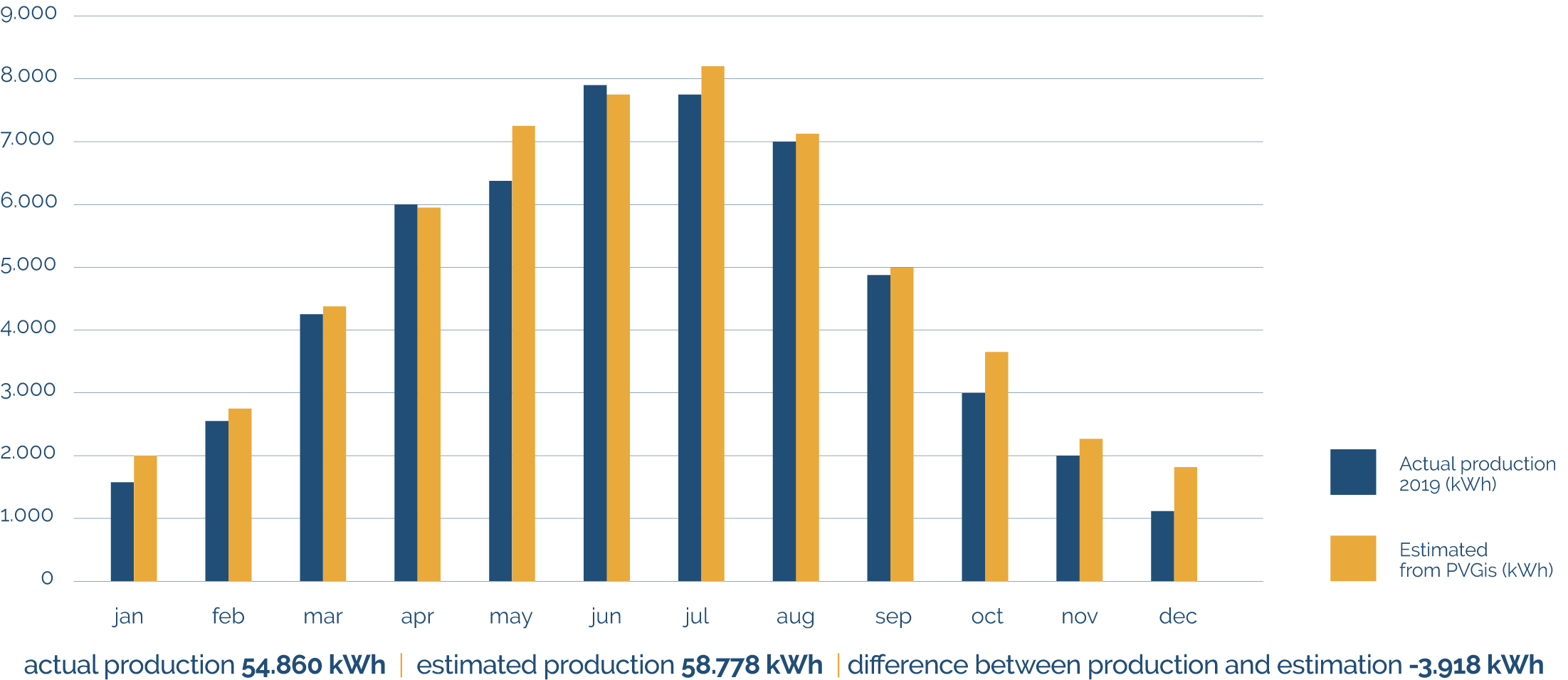

PRODUCTION vs ESTIMATION COMPARISON

Self-consumption 91%

Feeding into the network 9%

32 barrels of oil not extracted

-23 tonnes of CO2

117 saved trees

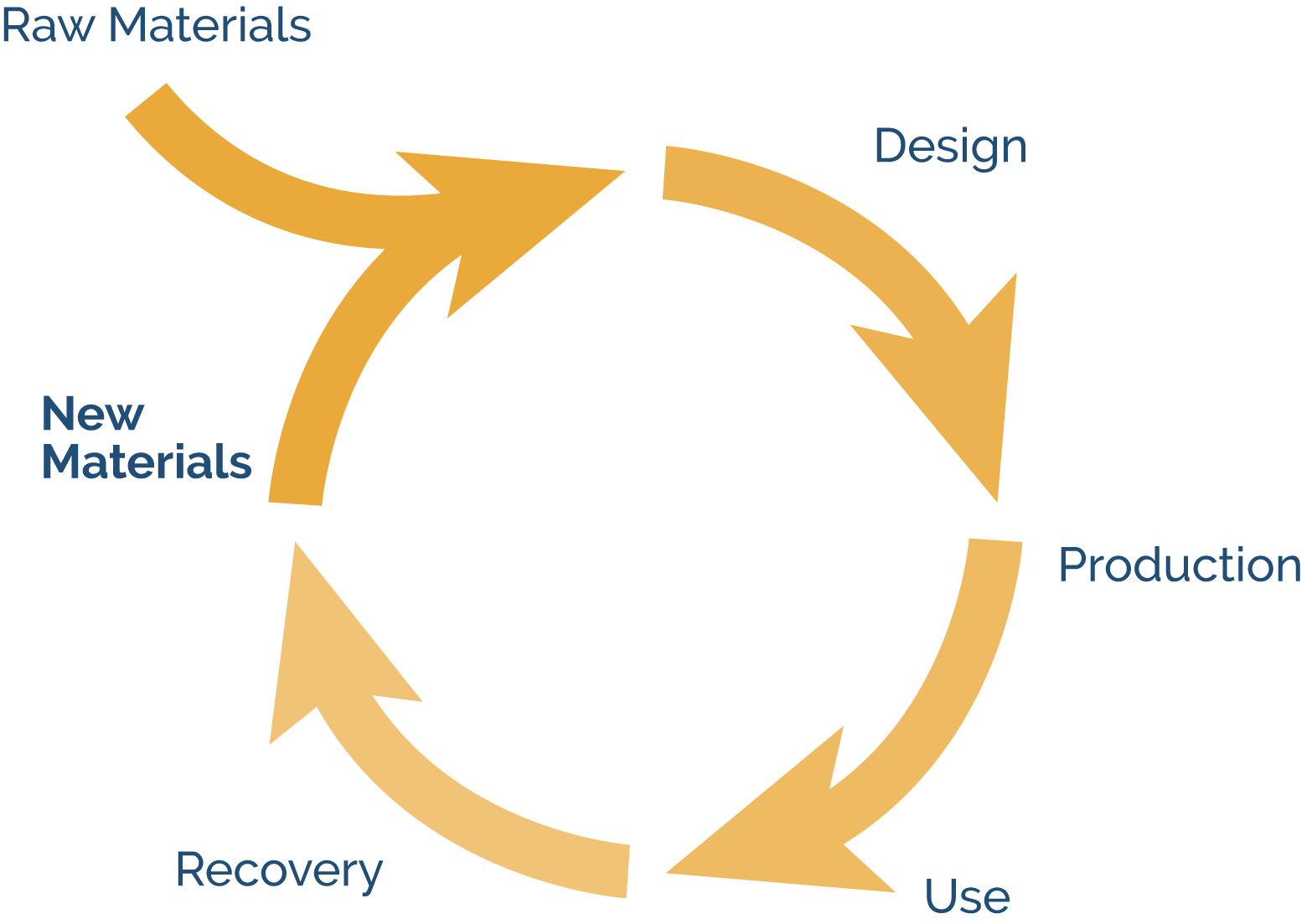

Thanks to constant technological updating, in collaboration with the Naples University Federico II, we are able to regenerate carbide at the end of its lifespan, an important achievement that places us among the first Italian companies to adopt a circular economy model in the industry.

Our company uses materials that are 100% recyclable at the end of their lifespan. Tungsten and cobalt are materials that are needed in many industries, which is why it is important to manage these resources sustainably in order to ensure quality carbide solutions in the future as well.

Regenerating carbideis a profitable and intelligent choice that aims at sustainability and supply optimisation.

Regenerating means protecting the environment because fewer resources and energy are used than in mining. In fact, producing tools from recycled materials requires 70% less energy and results in a 40% reduction in carbon dioxide emissions.

Before replacing the tool, check whether it can be repaired or regenerated. Regenerating or grinding can extend the lifespan of the tool.

You too can adopt a circular economy model

If you have end-of-life carbide, we can enhance it. CALL US or fill in the form below and you will receive an offer in a very short time