Starting from the sintered raw state, hardmetal parts can be finished according to the desired shape, size, flatness and finish of the surface.

Such operations are performed by grinding with specific diamond grinding wheels or by applying the EDM (Electrical Discharge Machining) technique.

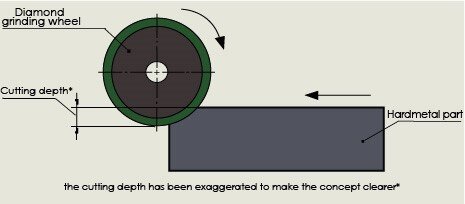

Conceptually, the grinding operation is outlined in the image below:

Diamond grinding wheel

The cutting depth has been exaggerated to make the concept clearer

In simple terms, the act of grinding can be defined as the removal of unwanted material.

During hardmetal grinding, the exposed diamond particles on the grinding wheel come into contact with the hardmetal tool to be refaced. As a result, the removal of material from the piece creates micro-chips. At this point, the work piece is subjected to an alternating or rotating movement and the grinding wheel is lowered by the “cutting depth”.

The process is repeated a number of times until an unwanted layer of material has been completely removed.

The factors that determine the grinding speed are:

The granulometry of the diamond plays an important role – a coarse grain facilitates a high rate of material removal in a relatively short amount of time, consequently, the worked surface can be coarse.

Diamond grinding wheels for working carbide

A sintered hardmetal tool has a surface finish of approximately 2-3 microns per mm and may have surface irregularities of a few hundredths of a mm in depth as a consequence of sintering treatment.

With proper diamond grinding wheels, the carbide surface can be improved until a lapped mirror finish is achieved.

To choose the proper grinding wheel, the following critical factors must be taken into due consideration, in accordance with the quality of the work to be obtained:

Mainly used for working cylindrical, conical or contoured surfaces, both externally and internally. The piece to be ground is mounted on a slowly rotating chuck which, in turn, rotates around a faster spinning grinding wheel, thus removing the material. A similar principle is used for chip removal in crankshaft grinding machines.

These are used for machining long, thin and small pieces that are not suitable for mounting on a chuck and tailstock assembly. In this procedure, the piece is machined between two grinding wheels — a larger one designed to sharpen the piece, and a smaller one used to push the carbide tool against the larger grinding wheel.

These grinders work on flat surfaces and include:

– Tangential grinding machines

– Frontal grinding machines

In tangential hardmetal grinding, the grinding wheel shaft is parallel to the plane being machined by the grinding wheel’s cylindrical surface; whereas in frontal grinding, the shaft is perpendicular to the plane being frontally machined by the grinding wheel.

Defects resulting from grinding

During the grinding process, thermal shocks may be provoked due to the loss or reduced flow of refrigerant or improper working parameters. Thermal shocks cause cracks on the hardmetal surface due to difference in temperature between the surface and the internal part caused by different thermal expansions.

The cracks can be microscopic, visible only under a microscope or with penetrating liquids. They can also be macroscopic, visible to the naked eye.

For this reason, the use of coolant is always recommended when grinding, even though it is possible to perform dry machining with specific grinding wheels. Some tips that can help prevent problems include:

When machining steel-bonded hardmetals, a crack can almost certainly be found in the hardmetal if the steel turns blue. Avoid this condition.